RFID Labels – HF, NFC, UHF Smart Labels

RFID labels, also known as “Smart labels”, are identifiers with memory support, which have the form of real adhesive labels, able to exchange radio frequency information with dedicated devices (RFID controllers).

Rfid labels, like any RFID transponder, are composed of a silicon chip and an antenna assembled on a special support and they have the task of identifying objects or people, in a unique and automatic way.

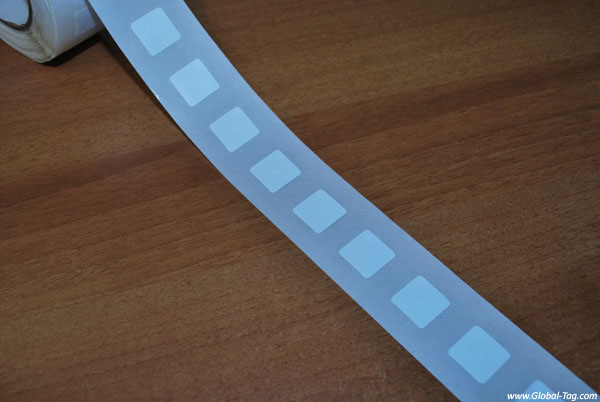

The RFID labels, supplied in rolls, can be printed and coded by means of special printers with thermal transfer technology or direct impression.

There are many variables and possibilities of choice / customization within the world of Smart Labels: our productions guarantee a high degree of flexibility in every aspect: available frequencies, chips, formats, sizes, materials, prints and codings.

Smart Labels can be produced in HF 13.56Mhz frequency (ISO14443 or ISO15693), UHF 860-960Mhz, or in double frequency for special applications.

The HF 13.56 MHz band is considered the universal band and it is used worldwide for applications such as access control, identification, payment, baggage control, laundry and library management, etc..

The latest generations of chips for this type of TAG support the anti-collision function that allows the reading/writing of multiple tags simultaneously present in the field of the Reader.

Unlike in the UHF band, the 13.56 MHz RF field is not particularly affected by water or human body tissues.

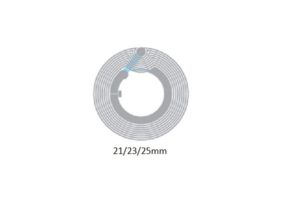

HF RFID tags operate at 13.56 MHz and it can be ISO/IEC 14443 or ISO/IEC 15693.

The ISO/IEC 14443 standard is defined as “proximity” and covers reading distances of up to 12cm; this standard is that of NFC technology implemented in most smartphones and tablets.

The ISO/IEC 15693 standard is defined as “vicinity” and covers reading distances up to a maximum of 130cm.

The UHF RFID band is the most recently introduced and it is the preferred band in logistic and asset management areas. The reading distance is significantly greater than HF tags one, with a reading range of up to 12-15 meters but, in exceptional cases, touching even 30 meters.

The reading distance of a UHF RFID tag is heavily influenced by the transmission power of the reader, the size of the tag’s antenna and the characteristics of the environment. Metal and liquids, in fact, attenuate the signal thus reducing the communication range.

The tag-controller coupling occurs by electromagnetic means, in HF tags mainly by magnetic field, while in UHF tags the prevailing component is of electric type.

The reference standard is ISO/IEC18000-6 Type C and the communication protocol between tags and controllers is called ‘EPC “Class1/Generation2”. The anti-collision system is even more optimized, allowing multiple readings, which exceed 100 tags per second.

Our standard products

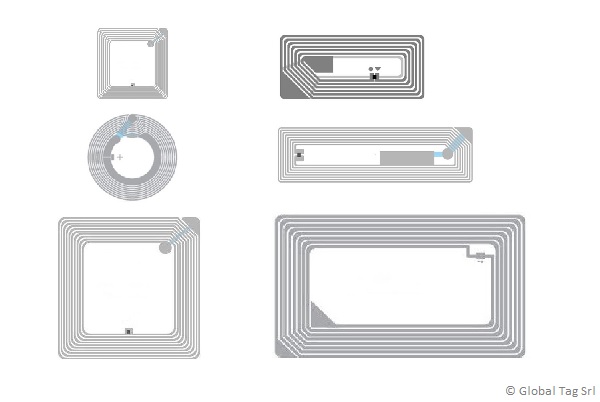

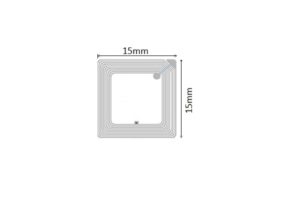

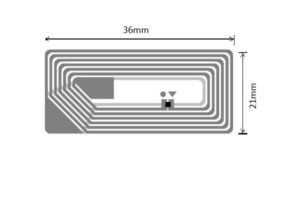

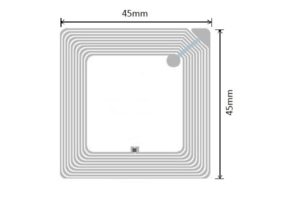

Our antenna designs differ in size and performance and they cover the most of needs of RFID projects that require inlays, wet inlays or RFID labels / stickers. The range of standard products combines high quality with competitive prices, made possible by the economies of scale of our production. Here is the rich proposal of HF and UHF tags.

HF (13,56 Mhz)

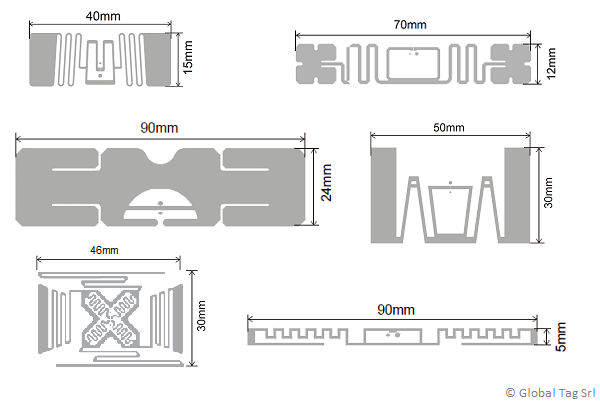

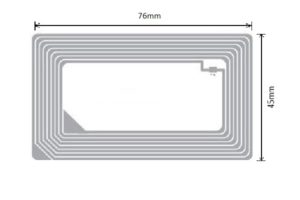

UHF (860-960 Mhz)

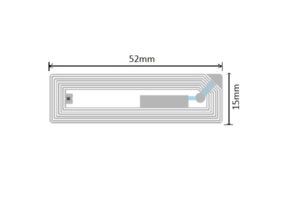

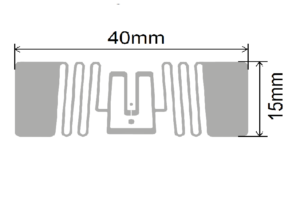

Antenna size: 40x15mm

Label size: 43x18mm

Available IC chip: U-Code 8

Reading distance: 6m

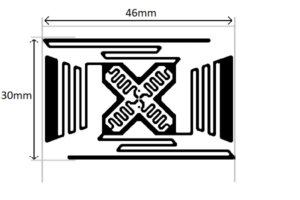

Antenna size: 46x30mm

Label size: 52x32mm

Available IC chip: Monza4QT

Reading distance: 5m

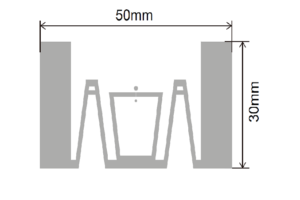

Antenna size: 50x30mm

Label size: 54x34mm

Available IC chip: U-Code 8

Reading distance: 6m

Antenna size: 70x12mm

Label size: 74x16mm

Available IC chip: U-Code 8

Reading distance: up to 9m

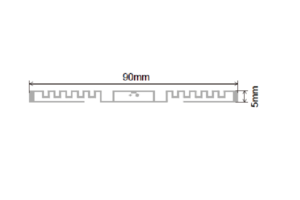

Antenna size: 90x5mm

Label size: 93x8mm

Available IC chip: U-Code8

Reading distance: Up to 5m

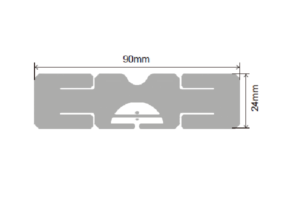

Antenna size: 90x24mm

Label size: 93x27mm

Available IC chip: Monza4QT

Distanza di lettura: Up to 5m

Available Types

Each antenna design can be expressed into 4 products, which differ in workmanship, physical features and cost. Depending on the project requirements, it is possible to opt for dry inlay, wet inlay, coated paper label or plastic label.

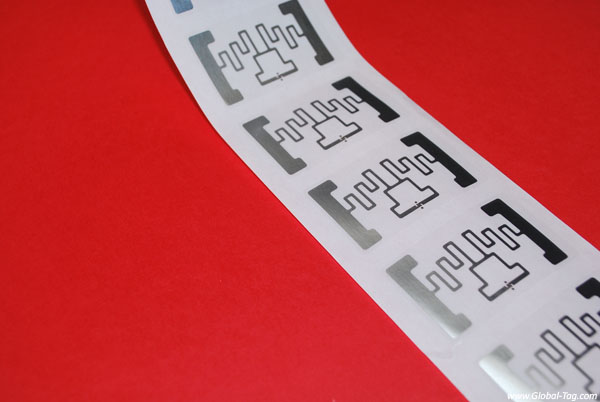

Dry Inlay

The inlay is the basic component of an RFID label: it is the special substrate on which the antenna, the chip and the capacitor are placed. It does not have any die-cutting, adhesive or cover (plastic or paper). Due to the absence of additional processing, it is the most inexpensive product.

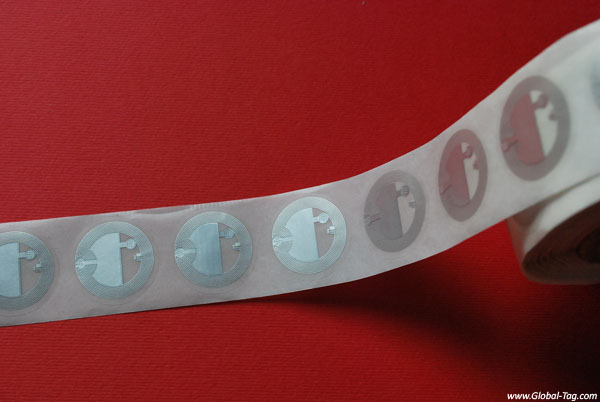

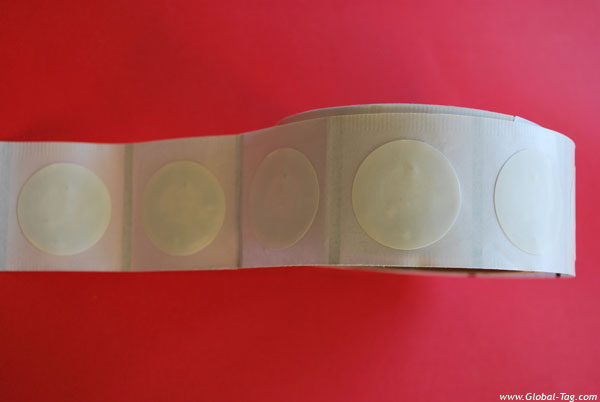

Wet Inlay

The wet-inlay is the next step: it has die-cutting, adhesive and a transparent polypropylene cover. This product, which has a visible antenna, can already be considered an RFID label in its own right. The main limit is the impossibility of printing the surface.

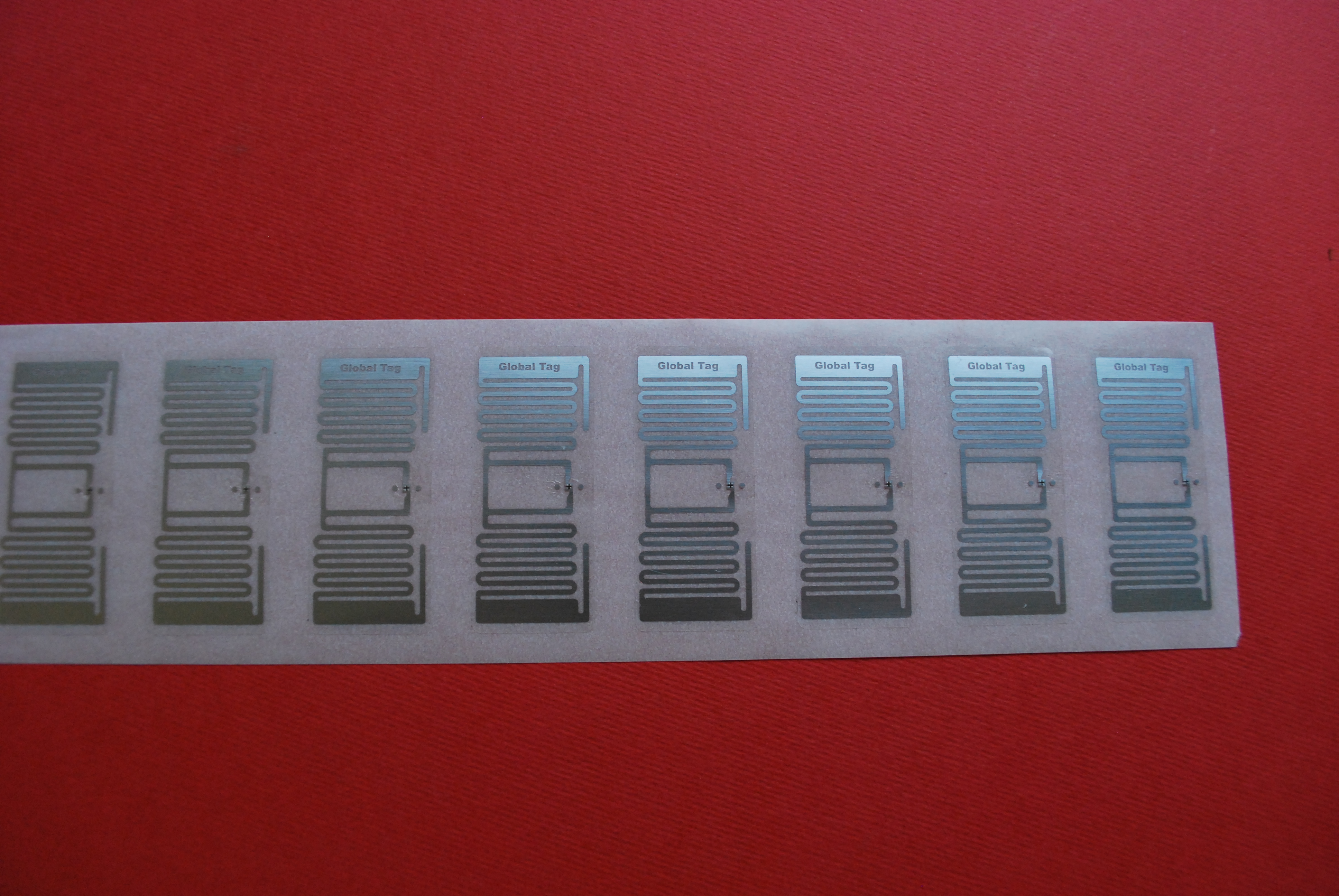

Coated paper labels

This product differs from wet-inlay in that it has a paper surface, which allows it to be printed on printers with an integrated RFID module. The paper RFID label is supplied in rolls and, on request, can be coded and/or printed by us during production.

Plastic surface label

To ensure better resistance to atmospheric agents and to increase the useful life of the product, it is advisable, where necessary, to opt for the Smart Label with one of the proposed plastic surfaces. Depending on the requirements, the materials used for the covering are PP, PET and PVC.

Customization

THERMAL TRANSFER PRINTING

Monochrome printing, performed with printers with integrated RFID module. It allows to print variable contents such as consecutive values, serial numbers from xls files, bar codes, and QR codes. The advantage of this option is that it is possible to print directly on site on behalf of the customer, for maximum flexibility.

OFFSET PRINTING

Four-colour printing with dedicated printers. It allows to print contents in high definition, starting from the vectorial file provided by the customer. This printing technique allows you to maximize the duration of stay of the contents, especially if the surface chosen is plastic (PVC, PP or PET).

LASER ENGRAVING

Laser engraving is a technique of content impression, used to print variable values (serial, progressive, barcode, QR,..) on labels in single format, i.e. not supplied in rolls. This type of printing is suggested when the smart label is subject to unfavorable environmental conditions or frequent friction.

- UID (or TID) - serial number association in datasbase

- User memory encoding of HF/NFC/UHF tags

- Encoding of UHF tag EPC memory

- Record of UID (HF) codes inside EPC memory (UHF) in dual frequency (HF+UHF) tags

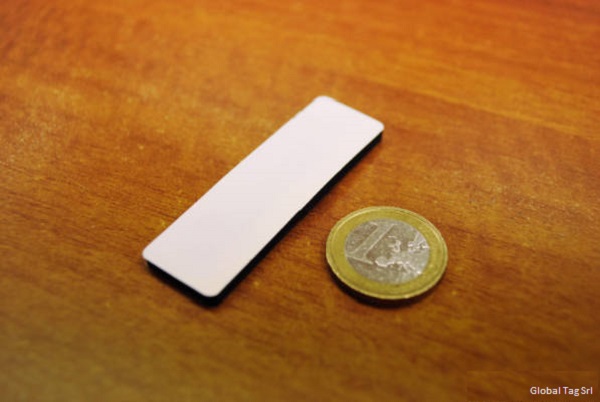

ON-METAL LABELS

Metal surfaces disturb radio frequency data transmission and make standard tags undetectable by the controller. This environmental limit can be exceeded by proposing dedicated RFID tags for metal. On-metal tags are RFID tags to which a layer of insulating material is applied and whose operating frequency is specifically modulated to optimize RF performance.

ETICHETTE RFID CON SPUGNA

Sometimes irregular surfaces prevent the attachment of self-adhesive RFID tags. The addition of a foam layer and the choice of the right adhesive offer a significant improvement in adhesion, which increases the life of the RFID/NFC tag.

Depending on the needs and the material from which the surface is composed, the thickness of the foam layer may vary.

ANTI-TAMPER LABELS

Anti-tamper labels are made of a special anti-burglary material. Removal attempt of the label from the surface to which it is applied will imply the breakage of the smart label antenna, creating an irreversible damage to the tag, which will no longer be readable.