BENEFITS

Guaranteed uniqueness and certainty in reading systems

Real-time results

Correct execution of maintenance

An Italian company operating in the elevator maintenance sector was looking for a system that could guarantee greater efficiency and accuracy in the executive management of the control process. In particular, they were lookong for a solution with which they could assure the technicians that they were on the correct installation and the company itself the certainty that its workers were actually on the right structure. To allow all this, RFID technology was implemented.

How does RFID contribute?

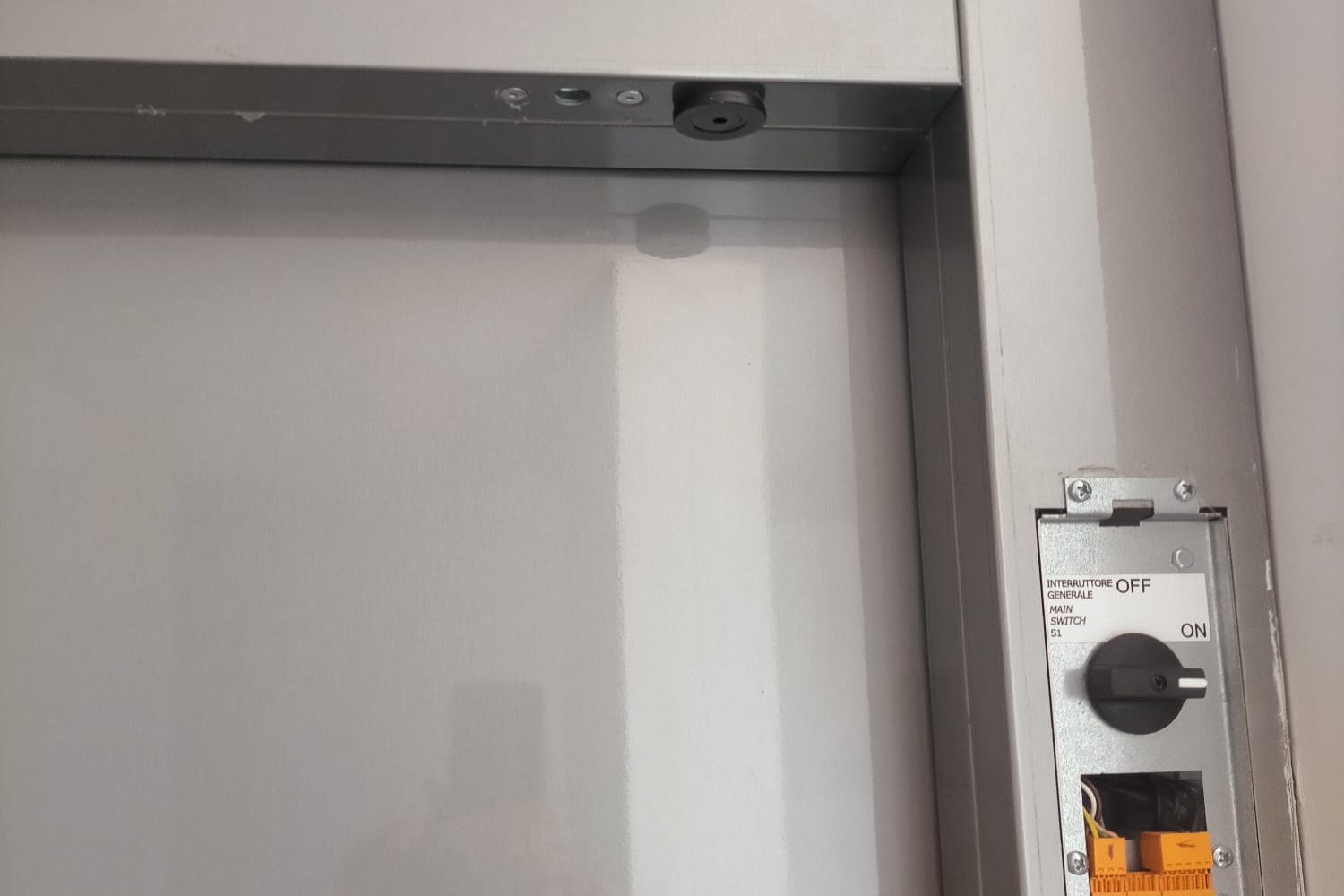

The tag chosen to satisfy these needs was the Tokky34, which is an extremely robust on-metal transponder with a circular shape, ideal for use in industrial environments such as elevator maintenance and equipped with IP68 protection, which guarantees greater resistance and duration. However, the main reason that led to the decision – taken in agreement with the customer – to use this tag was the ease with which the Tokky34 can be riveted onto any type of surface – even the less homogeneous ones such as the metal ones of elevators – thanks to the presence of a central hole and an adhesive sponge on the back. Furthermore, working in HF frequencies, this tag fits perfectly with the limited reading distances required to guarantee the effective presence of the maintenance technician on the system.

The transponder is then placed on the elevator and allows the technician to verify that he is on the correct lift simply by bringing a device (supported by NFC technology) close to the tag itself, equipped with a unique identification code. With this quick operation the operator can have access to all the necessary data for elevator maintenance loaded into the Tokky34 memory, while when he is in the wrong station he is redirected to the right system via an acoustic signal that signals the discrepancy. Once the work is finished, the information will be automatically recorded and transmitted to the management system, allowing the planning of future interventions or the reporting of any problems.

RFID technology therefore makes it possible to manage the maintenance process by guaranteeing the uniqueness and certainty of reading the various systems. In this way the results of the work carried out by the maintenance technician are visible in real time and the company can ensure that the technical control is carried out according to the pre-established procedures.